Electrical testing and tagging, commonly referred to as Test and Tag, is a vital safety procedure designed to safeguard individuals, property, and businesses. The purpose of this process is to identify hidden faults in electrical appliances before they become hazardous.

In addition to accident prevention, regular testing guarantees adherence to workplace safety standards, fulfills insurance obligations, and instills confidence in employees regarding their work environment. Whether in offices, construction sites, healthcare institutions, or educational facilities, implementing a comprehensive test and tag program serves as a proactive measure to mitigate risks and enhance operational efficiency.

What is Electrical Testing & Tagging?

Electrical testing and tagging, commonly known as Test and Tag, involves the following steps:

1. Conducting a visual inspection of electrical appliances and equipment to identify any damage or signs of wear.

2. Performing electrical tests using specialized portable appliance testers (PAT).

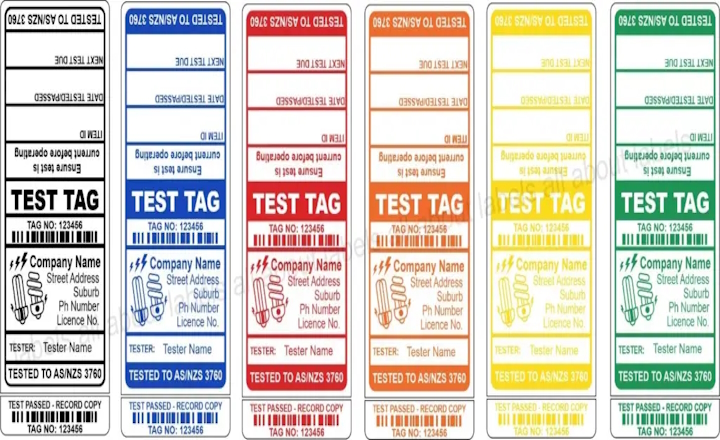

3. Affixing a durable label to the equipment that displays the test date, the next scheduled test, and the technician’s information.

This process ensures that each device is safe for use and complies with local workplace safety regulations.

Why is it Important?

Ensures Safety of People and Property

Defective electrical devices can result in fires, electric shocks, or even fatalities. Regular testing significantly reduces these risks by identifying potential hazards before they can cause harm.

Compliance with Regulations

There are numerous countries that require regular testing and tagging as part of workplace safety legislation (for instance, AS/NZS 3760 in Australia). Failure to comply can result in fines, insurance issues, or legal repercussions.

Reduces Equipment Downtime

Through regular testing, preventive maintenance can be implemented to detect potential failures early, ensuring that critical equipment remains operational and reducing unexpected downtime.

Boosts Workplace Confidence

When employees and visitors are aware that appliances undergo regular testing and tagging, it enhances their confidence in the safety of the work environment.

Insurance Requirements

The insurance company often requires evidence of regular electrical maintenance as a condition of the policy. Testing and tagging help fulfill these requirements, facilitating smoother claims if necessary.

What happens if you don't test and tag electrical equipment?

In the event of an electrical accident occurring without prior testing and tagging of the item, the employer may be held liable. This liability could result in fines or other legal consequences. Additionally, it may affect insurance policies, as some require proof of compliance. This is relevant across all industries, including those not specifically mandated, such as office environments.

However, if a compliance issue arises in a more regulated sector, such as construction sites, WorkSafe for that specific state has the authority to shut down sites and impose fines.

The degree of severity and the resulting consequences will depend on the specific circumstances surrounding the incident. To mitigate potential legal and financial liabilities, as well as to safeguard employee safety, it is far more straightforward and secure to incorporate testing and tagging into your safety protocols.

But are we legally obligated to conduct testing and tagging?

Testing and tagging serve as an effective method for ensuring the electrical safety of all fittings and appliances within the workplace. Nevertheless, it is not a legal requirement to perform these actions. The decision to implement regular testing lies with the Person Conducting Business or Undertaking (PBCU).

By engaging in testing and tagging, you are taking prudent measures to uphold electrical safety in your workplace. This practice also conveys to employees that you are taking appropriate steps to avert electrical accidents and injuries.

Many faults in appliances are not readily apparent; therefore, testing and tagging can help identify risks associated with fires or electric shocks. It is unrealistic to assume that an appliance is entirely safe, especially if it is older or has been heavily used.

Who Requires Testing and Tagging?

Offices and Commercial Spaces

Construction and Mining Sites

Workshops and Factories

Schools and Educational Institutions

Healthcare Facilities

Event Venues and Pop-up Installations

In essence, any business or environment that utilizes electrical equipment in a public or shared setting should establish a test and tag program.

How Frequently Should it Be Conducted?

The frequency of testing and tagging is influenced by:

- The type of environment (for instance, construction sites necessitate more frequent testing).

- The nature of equipment usage (high-use or high-risk tools require more regular inspections).

- Local laws and regulations.

For instance, in high-risk environments, such as construction, equipment may require testing every three months, whereas in a low-risk office setting, it may be tested every twelve months.

Conclusion

In contemporary workplaces, electrical safety must not be left to chance. Testing and tagging provide a straightforward yet practical approach to prevent hazards, ensure regulatory compliance, and extend the lifespan of essential equipment.

| < Prev | Next > |

|---|