Construction projects require coordination across multiple teams, strict scheduling, cost control, and consistent safety compliance. As projects grow more complex, manual tracking methods such as spreadsheets, phone calls, and paper documentation often lead to delays and communication gaps. Construction site management software provides a centralised digital solution that improves oversight, streamlines workflows, and enhances accountability across job sites.

What Is Construction Site Management Software?

Construction site management software is a platform designed to manage and monitor daily site operations. It connects field teams, supervisors, and office personnel within a unified system that tracks scheduling, documentation, reporting, and resource allocation.

Instead of relying on disconnected tools, companies can operate from a single dashboard that delivers real-time updates. This structured approach reduces errors and ensures all stakeholders have access to consistent information.

Key Features of Site Management Platforms

Modern platforms are built to address common operational challenges in construction environments.

Project Scheduling and Task Tracking

Managers can assign tasks, set deadlines, and monitor progress in real time. Updates are instantly reflected across the system, helping teams remain aligned and reducing scheduling conflicts.

Centralised Document Control

Construction sites generate blueprints, permits, inspection reports, and compliance records. A centralised repository ensures that authorised users access the latest document versions, reducing mistakes caused by outdated information.

Communication and Field Reporting

Integrated communication tools allow field workers to submit updates, upload photos, and complete reports directly from mobile devices. This minimises delays and improves coordination between job sites and office teams.

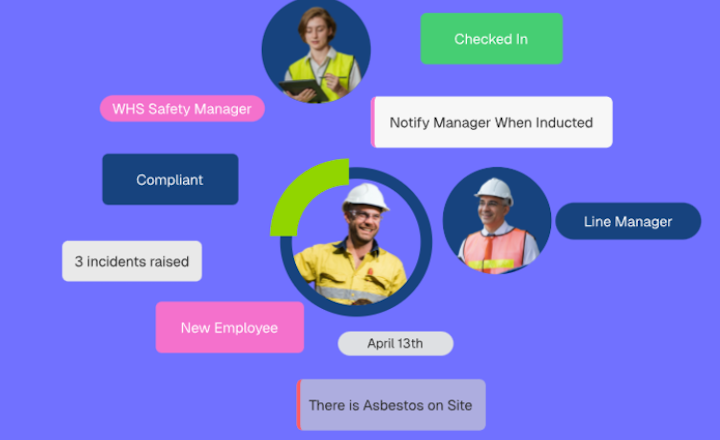

Safety and Compliance Monitoring

Digital safety checklists and incident reporting tools help maintain regulatory compliance. Organised digital records simplify audits and provide documentation when needed.

Resource and Equipment Management

Tracking labour hours, equipment usage, and material deliveries ensures efficient allocation of resources. This reduces downtime and supports better cost management.

Operational Benefits

The adoption of construction site management software offers measurable improvements across projects.

Improved Visibility

Real-time dashboards provide leadership with insight into project progress, productivity, and financial performance. Early identification of issues allows for proactive solutions.

Reduced Errors and Rework

Working from a centralised system decreases miscommunication. Teams operate from one source of truth, minimising costly rework.

Better Cost Control

Monitoring labour, material, and equipment expenses in one platform helps managers compare projected budgets with actual spending.

Higher Productivity

Automation reduces administrative workload, enabling supervisors to focus on managing operations rather than paperwork.

Enhanced Accountability

Digital logs create transparent records of assignments, approvals, and updates, strengthening responsibility across teams.

Cloud and Mobile Accessibility

Most modern construction site management platforms operate in the cloud. This allows users to access project information from any location, which is essential for organisations managing multiple job sites.

Mobile compatibility ensures that field personnel can complete inspections, upload images, and update task statuses directly from smartphones or tablets. Information synchronises instantly, eliminating communication delays between on-site and office staff.

Cloud deployment also provides secure data storage and automatic software updates without requiring complex IT infrastructure.

Data-Driven Decision Making

Construction projects generate significant operational data. When properly organised, this data provides valuable insights into productivity trends, safety performance, and cost efficiency.

By consolidating metrics into visual dashboards, site management software allows managers to identify inefficiencies and refine processes. Over time, data-driven oversight supports better forecasting and long-term planning.

Companies seeking structured digital oversight often evaluate platforms offering comprehensive construction site management software to centralise supervision, compliance tracking, and reporting within a single system.

Implementation Considerations

Successful implementation requires clear onboarding and structured training. Companies should define standardised workflows within the system to ensure consistent reporting across all projects.

Leadership engagement plays a key role in adoption. When supervisors actively use the platform, team members are more likely to follow established processes. Proper planning during rollout reduces disruption and accelerates integration into daily operations.

Conclusion

Construction site management software provides a practical framework for coordinating complex job site activities. By centralising scheduling, documentation, communication, safety monitoring, and resource tracking, it strengthens operational control and reduces risk.

Cloud-based access and mobile functionality enhance collaboration between field and office teams. As construction demands continue to grow, implementing a reliable digital site management solution is essential for improving efficiency, maintaining compliance, and delivering projects successfully.